Technological shifts across industrial infrastructure have pushed businesses to prioritize smarter, leaner hardware integrations. Standard solenoids no longer offer the data granularity or responsiveness that modern facilities demand.

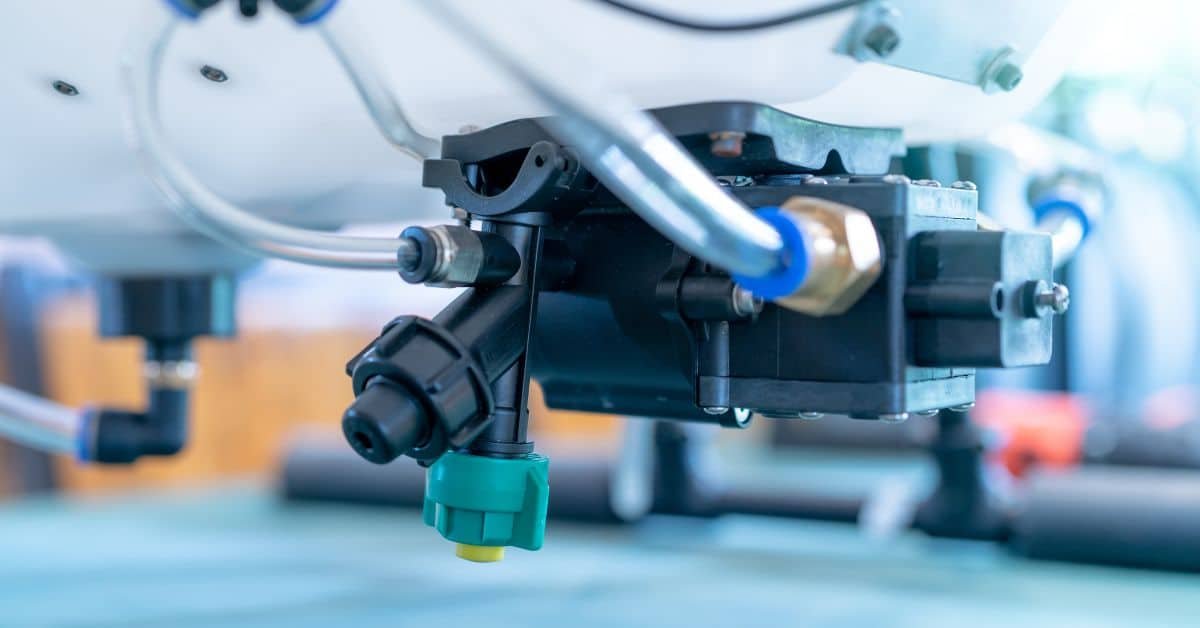

Smart solenoid systems fill the gap with communication capabilities, sensor-driven feedback, and seamless connectivity to broader digital ecosystems. Professionals who oversee facility operations increasingly rely on smarter actuation devices to drive performance improvements across every level of infrastructure.

Enhanced Operational Control and Monitoring

Smart solenoid systems allow remote tracking of actuation events, voltage levels, and response cycles without direct physical access. In automotive factories, the evolution of solenoids resulted in improved visibility into valve health, pressure changes, and command signals by pairing solenoids with diagnostic software and embedded sensors.

One major advantage of smart solenoid systems in facilities is the ability to identify anomalies in real time before they cause operational delays or require emergency service. Smart systems also provide operators with the ability to adjust behavior based on changing conditions.

Data-Driven Predictive Maintenance Capabilities

Facilities that install smart solenoids collect vast amounts of time-stamped diagnostic data, which builds performance models over time. Historical data allows technicians to spot subtle shifts in actuation speeds, power draw, or cycle frequency long before traditional inspections would notice. Predictive algorithms use this data to recommend targeted service intervals based on system behavior, not fixed timelines.

Another significant advantage of smart solenoids systems in facilities is their ability to support proactive strategies instead of reactive maintenance. Scheduled checkups driven by AI-supported alerts allow technicians to resolve root causes before valve stalls or electrical failures occur. This level of foresight increases asset longevity while minimizing the operational risks that accompany traditional reactive service models.

Scalability for Large-Scale Digital Systems

Digital facilities require actuation hardware that integrates into centralized control systems without custom retrofits or middleware. Smart solenoids provide plug-and-play compatibility with programmable logic controllers, SCADA platforms, and IoT device networks.

Engineers create macros, time-based sequences, and priority-based overrides from the same interface used to control temperature, lighting, or ventilation. When solenoids support wireless updates, remote configuration, and fault notification, facilities avoid disruptions during expansion or upgrades.

Long-Term Efficiency and Cost Optimization

Smarter solenoids reduce wasted electricity and air by responding faster and sealing more precisely during every actuation cycle. Shorter delays between command and valve movement reduce pressure leaks and mechanical friction, contributing to lower operational overhead. Fewer breakdowns and faster identification of failure modes translate into reduced long-term repair costs across high-volume systems.

Operational efficiency improves when actuators coordinate with other components in a synchronized digital environment. Instead of triggering at fixed intervals, solenoids respond dynamically to sensor thresholds, environmental conditions, or energy load balancing requirements. Transitioning from legacy solenoids to smart systems often see gains in sustainability metrics, energy usage tracking, and regulatory compliance.

Smart solenoid systems create strategic value in digitally connected operations. Integrated monitoring, predictive diagnostics, and flexible control empower teams to make smarter decisions across the entire infrastructure. Teams can leverage tech to operate leaner, smarter, and with fewer surprises.

Explore similar articles:

5 Industries That Rely on Reverse Engineering

Interesting Facts About Comm Towers and Their Purposes

At CIO TechWorld, I architect global revenue strategy, cultivate enterprise alliances, and engage directly with CXO leaders shaping the future of technology.

Operating at the convergence of editorial intelligence, commercial strategy, and executive influence, I specialize in transforming complex business objectives into authoritative market presence.